Description

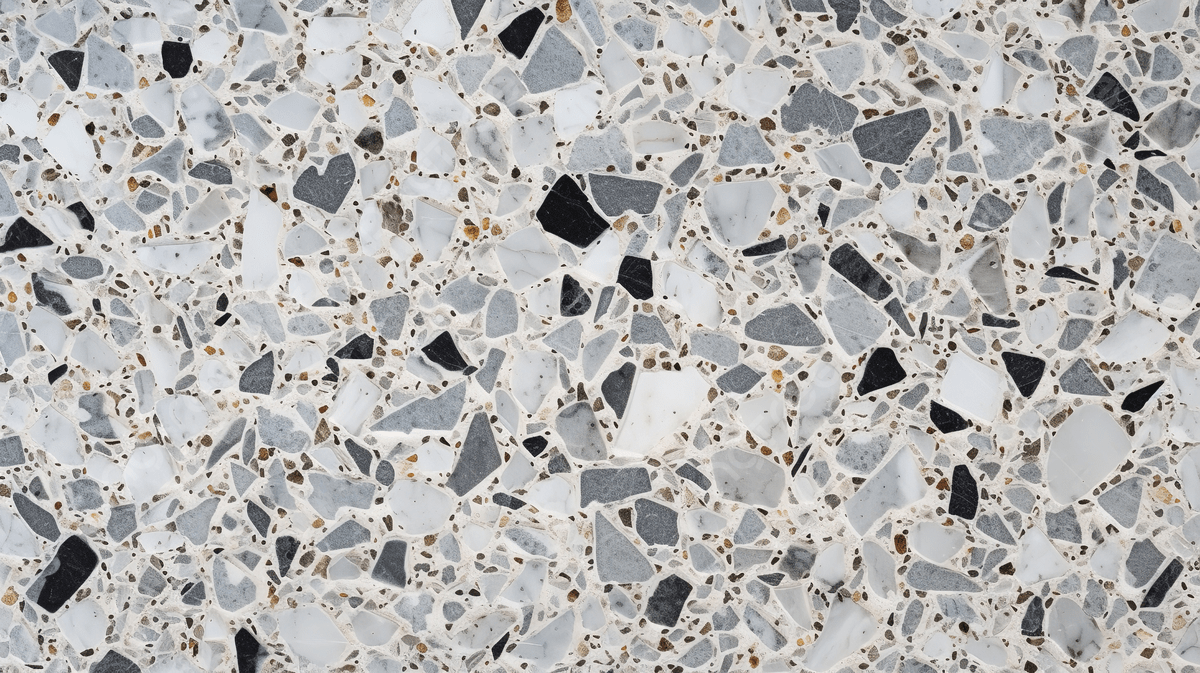

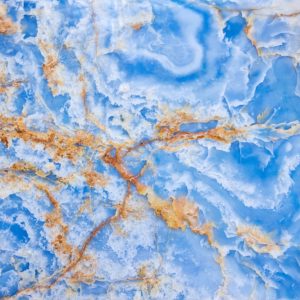

Terrazzo slabs are precast composite stone panels made by mixing aggregates (such as marble, granite, quartz, or glass chips) with a binder — usually cement-based or epoxy resin. The mixture is cast into slabs, cured, and then ground and polished to a smooth finish. These slabs are cut and fabricated like natural stone and are used for countertops, vanity tops, wall cladding, tabletops, stairs, and tiles.

Qualities (Pros):

-

Factory-Made Consistency: Produced under controlled conditions for consistent color, pattern, and quality across slabs.

Highly Customizable: Wide range of aggregate colors, sizes, and binder tones to match design schemes.

Sustainable Options: Often includes recycled content (e.g., post-consumer glass, stone chips), supporting green building goals.

Versatile Applications: Can be used horizontally (e.g., countertops, benches) or vertically (e.g., walls, facades).

Polishable Surface: Can be re-polished over time to restore shine and remove light surface wear.

Limitations (Cons):

-

Heavy Material: Like stone, terrazzo slabs are dense and require proper structural support and handling equipment during installation.

Heat Sensitivity (Epoxy Resin): Epoxy-based terrazzo is not heatproof — hot pots or pans can damage the resin binder if placed directly on the surface.

Susceptible to Cracks: Slabs may crack or chip if not properly supported or if subjected to impact, especially along cut edges or corners.

Limited Outdoor Use: Epoxy terrazzo slabs are not UV-stable — may discolor or degrade in direct sunlight. For exterior use, cement-based slabs are preferred.

Higher Cost: Custom or large terrazzo slabs can be expensive, especially when made with high-end or rare aggregates.

Installation Requires Expertise: Like stone countertops, terrazzo slabs need professional fabrication and installation to ensure longevity and aesthetics.