Description

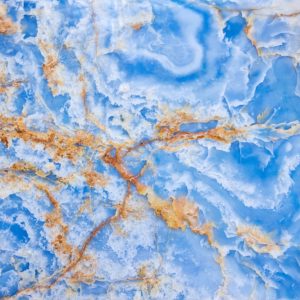

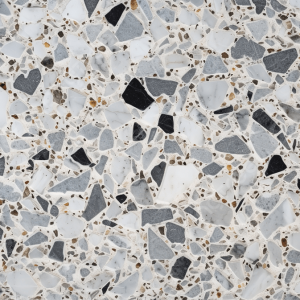

Mineral surfaces (also called reconstituted stone, or agglomerate stone) are man-made slabs created by combining natural stone particles (typically quartz, marble, or granite dust) with resins, pigments, and binders. The result is a non-porous, uniform surface designed to mimic natural stone while offering improved performance and consistency.

Qualities (Pros):

-

Consistent Appearance: Uniform color, pattern, and texture across slabs — no natural variation or veining mismatches.

Highly Durable: Resistant to scratches, cracks, and chips under normal use.

Non-Porous Surface: Does not absorb liquids, making it highly stain-resistant and hygienic — ideal for kitchens and bathrooms.

Low Maintenance: Does not require sealing; easy to clean with mild detergent.

Wide Range of Colors & Finishes: Can replicate natural stone or offer more modern, consistent aesthetics not found in nature.

Environmentally Friendly Options: Most brands incorporate recycled stone or glass.

Customizable: Can be manufactured in various thicknesses and finishes (polished, matte, etc.).

Resistant to Mold and Bacteria: Excellent for food preparation and wet areas.

Limitations (Cons):

-

Heat Sensitivity: The resin component can be damaged by high heat — not as heat-resistant as natural stone (e.g., placing hot pans directly can cause discoloration or cracks).

UV Sensitivity: Some reconstituted stones may fade or yellow over time if exposed to direct sunlight — not always ideal for outdoor use.

Less “Natural” Look: While high-quality versions look similar to stone, trained eyes may spot the lack of organic variation or depth.

Can Be Pricey: High-end reconstituted surfaces can be as expensive as natural stone.

Not Fully Recyclable: Resin content means it’s not as sustainable as pure natural stone when it comes to end-of-life disposal.